The science behind Climfeet

For whom?

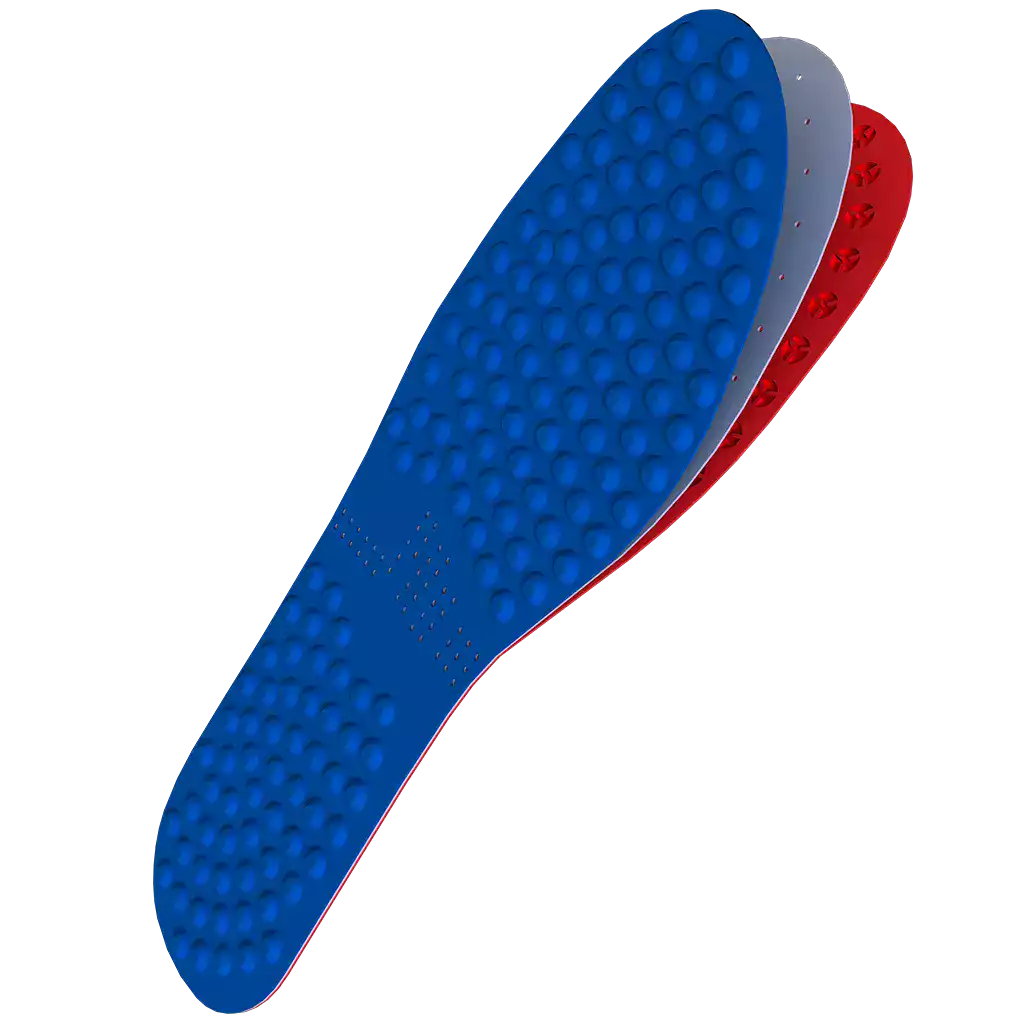

Professional or amateur athletes, workers in cold storage warehouses, construction & public works, as well as military personnel or firefighters, and even animals are often exposed to extreme conditions throughout the day or even longer. Feet are the most exposed parts to cold or heat as they are in direct contact with the ground. Putting CLIMFEET in your shoes will allow you to better regulate their temperature. Only a thermoregulation device that uses the energy from your own steps can help keep your feet warm or cool without any time limit (as long as you walk or run).

Thermodynamics

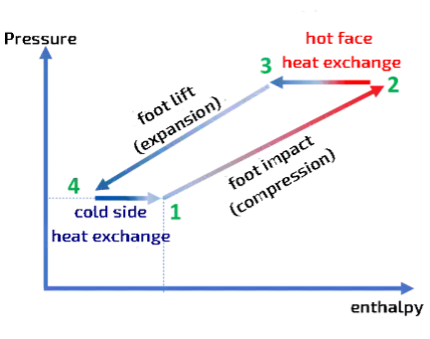

The principle adopted by the SoleCooler patent is based on thermodynamics, particularly on the Carnot cycle, like in an air conditioner but with air as the fluid, which is more environmentally friendly even though the efficiency will be lower.

To reproduce this thermodynamic cycle in an insole, we devised and patented a new process that uses foot pressure on the ground instead of a compressor: airtight, low-compression cells on one side and easily compressible airtight cells on the other, linked by a nozzle (a small, conical hole) to help compress and, above all, expand the air.

Compression/Expansion

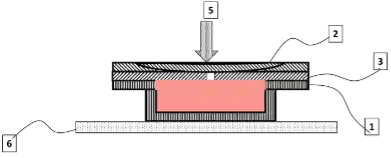

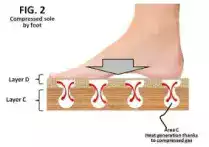

When the foot hits the ground, the air in the alveoli is compressed and heats up naturally (a bit like the warm-up you see with your bicycle pump).

Once compressed, when the foot is raised, the air is released through the nozzle and cools naturally (just like when you deflate your car tire: the air coming out is much cooler while the tire is warm)

Convergent/Divergent Nozzle

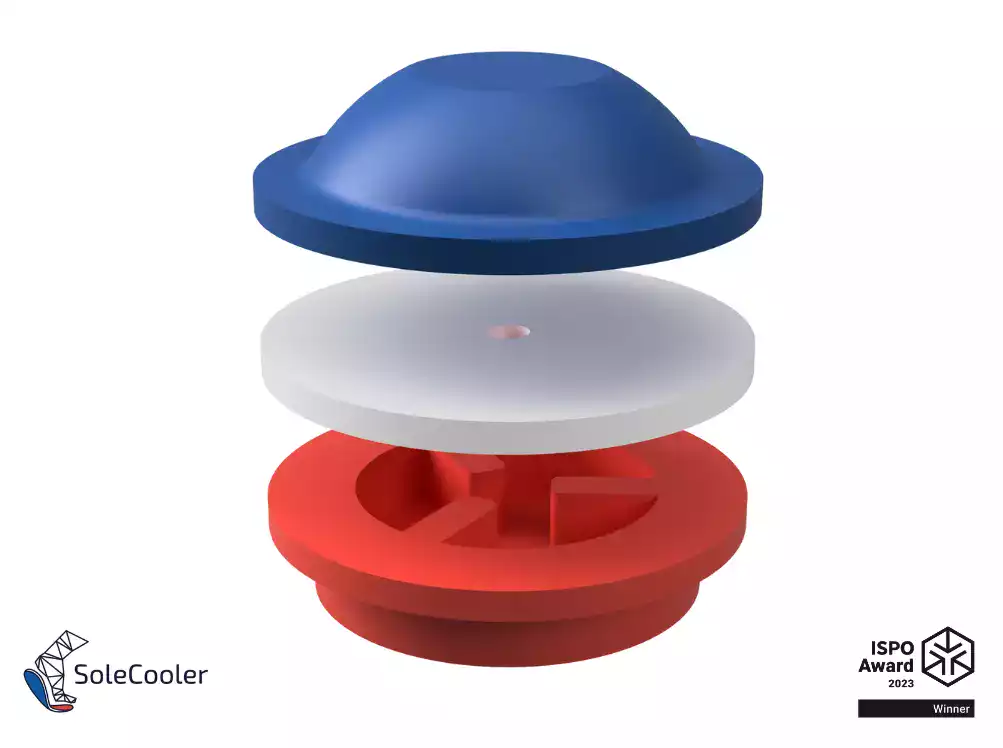

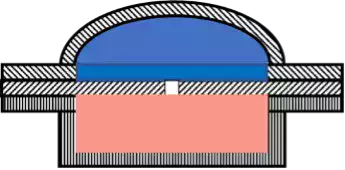

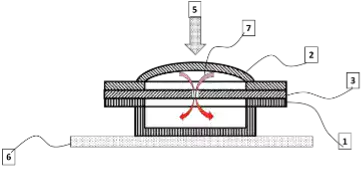

To reproduce these phenomena in an insole, we have conceived and patented a new process that uses the pressure of the foot on the ground instead of a compressor: Closed alveoli that consist of two parts made of two different materials and connected by a perfectly calibrated nozzle (similar to a rocket nozzle). One part is very flexible and, thanks to the foot pressure, compresses the trapped air in the second part, which is less flexible. Once the foot is lifted, the compressed air returns to the more flexible part through the nozzle, thus naturally cooling down.

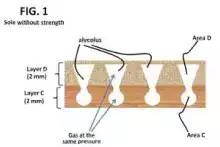

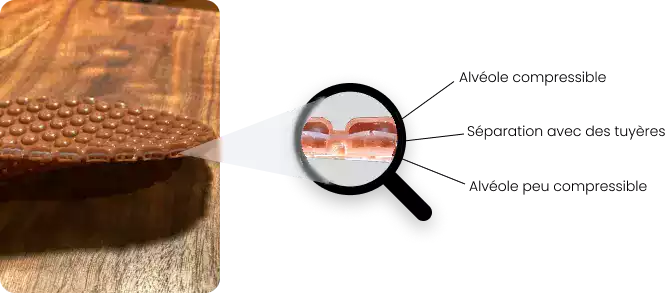

The alveoli

When the alveoli are cut, their structure can be seen:

- compressible alveoli

- low compressibility alveoli (with reinforcements)

- a separation between the 2 types of alveoli, with nozzles for air compression/expansion

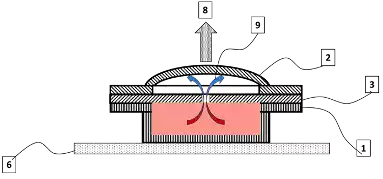

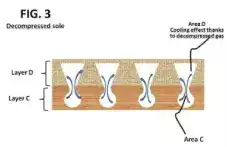

Operation of the technology of our alveoli

-

Compression of alveoli

Our technology works on the same principle as an air conditioner. Except your steps are the compressors!

Distribution of air and heat in the alveolus

Hot & Cold

Outside temperature: -20 ° C, a good challenge to warm up your feet. Here is a CFD simulation showing the temperatures obtained in an alveolus of our insoles thanks to compression/expansion during repeated foot placement.

Here are the temperatures obtained in the alveoli of our thermodynamic soles by the sole pressure of the feet. Without battery or chemical products and therefore without carbon footprint! All this would not have been possible without the help of the Ansys Start Up program, thank you.